Digging into Mine Rehabilitation: Underestimated Costs & Risks

November 2023

Introduction

The rehabilitation of mining sites is an important element of mining and best practice recommends that it should form part of a project from its inception and be a key part of a license application. It is a common occurrence for mines to underestimate rehabilitation costs, which causes earnings risks as earnings suffer when estimates are adjusted, provisions increased, and remediation work is eventually carried out. In this article we look at the causes behind rehabilitation cost increases using two examples to highlight broader sector trends.

Mine Rehabilitation

The Mining Act 1992 defines rehabilitation as “the treatment or management of disturbed land or water to establish a safe and stable environment,”1 and in Australia, rehabilitation is a legal obligation for mining companies. A recent Australian Geographic article points to significant delays and costblowouts that underpin a national legacy of 80,000 abandoned mine sites.2 The analysed footprint includes abandoned and heritage mines, but also those in a status of ongoing rehabilitation.

Miners usually commit to rehabilitation work when applying for a mining license. From an accounting perspective, an estimation of the mine rehabilitation cost and of the mine’s end-of-life are made, then discounted back to the present and included as a liability on its balance sheet. Provisions charged to the P&L are used in subsequent years to adjust the liability as required.

Rehabilitation costs may be driven higher for several reasons, including broad cost inflation as well as the initial underestimation of costs that only comes to light once work commences. Earlier than planned mine closures can also result in an increase in rehabilitation liabilities as disbursement timing is brought forward causing an increase in the present value of the liability.

When technically possible, commencing remediation works early in the areas already mined, whilst continuing to mine new areas can lead to more accurate estimates and reduce the risk of a cost blowout.

Water is often a complicating factor in mine remediation: it requires infrastructure to be contained (e.g. tailing dams) that can be compromised by technical problems and/ or be overwhelmed by unexpected weather patterns. When poorly controlled, water allows pollutants to seep into surrounding areas causing environmental damage that is difficult and costly to contain and remediate.

While cost inflation and initial underestimation play a part in widespread and recurrent mine rehabilitation cost increases, more stringent regulation, and changing community expectations seem to be the cause of the largest cost increases.

Mines usually run for several years and often for decades. In the period of time that mining companies make their preliminary remediation commitments and mine work commences, environmental legislation is likely to change, surrounding land uses in more populated areas can change, and community expectations in relation to stakeholder consultation, corporate behaviour and what constitutes an acceptable level of remediation are also likely to change. Needless to say, simply filling the hole with water and calling it a “recreational lake” is unlikely to meet current expectations, let alone accord with the law. Indeed, reforesting with new species is no longer deemed sufficient. Nothing short of returning the land to its original contour and replanting it with its native species is the current standard. Collecting seeds and cuttings prior to land disturbance and propagating them with the help of traditional owners is current best practice, with attention given to creating environments and corridors that encourage the return of native fauna.

The paper “International Principles and Standards for the Ecological Restoration and Recovery of Mine Sites”3 published by the Society for Ecological Restauration, The ARC Centre for Mine Restauration, and Curtin University and presented at the UN’s COP15 (Conference of Parties) in Montreal in November 2022 states:

“The quantity and quality of the ecological restoration and recovery of

mine sites has accelerated in the past two decades in response to legal and regulatory obligations, community and cultural expectations, and cumulative impacts to landscapes, watersheds, and biodiversity. Importantly, mining companies are increasingly aware of the need to maintain their social license to operate (SLO) in addition to legal requirements to achieve mine closure and relinquishment”.

The standards are underpinned by eight principles:

- Engage stakeholders throughout the life of mine.

- Draw on many types of knowledge.

- Be informed by reference ecosystems, while considering environmental change.

- Support ecosystem recovery processes.

- Assess against clear goals and objectives, using measurable indicators.

- Seek the highest level of recovery attainable.

- Gain cumulative value when applied at large scales.

- Employ a continuum of restorative activities.

In our analysis of two separate examples, we found that stakeholder engagement was critical to retaining a mine’s social license to operate and that changing community expectations resulted in rehabilitation cost increases ahead of any changes in regulatory obligations. In both cases, the miner’s desire to extend the scope of their activities (either in time or space) made it imperative for them to remediate their sites to the highest standards, going beyond their legal obligations to satisfy community stakeholders as this would give them the best chance of extending its mining licenses as required to underpin future earnings.

In both cases difficult relationships with external stakeholders resulted in tougher approval processes and the likely frustration of corporate expansion plans. Having a good working relationship with all stakeholder groups: neighbouring farmers, environmental groups, and – in particular, First Nation Groups, while likely to lead to increased remediation costs, seems the necessary cornerstone to retaining and extending mine licenses.

Both examples demonstrate the financial risks and a growing “sleeper”4 in the form of offbalance sheet liabilities, but also the challenges to corporate reputations and the associated social licence to operate that mine rehabilitation practices present.

The Ranger Uranium Mine Case

The rehabilitation of the Ranger Uranium Mine in the Northern Territory of Australia is currently estimated to cost between $1.6 and $2.2 billion (2022 Ranger Mine Closure Plan). That range is approximately double the estimate made in 2019. The rehabilitation of this site is particularly vexing for its radioactive ore, location separate to but surrounded by a World Heritage Site, and a fraught relationship with traditional owners.

Historically, the rehabilitation of uranium mines has been problematic in Australia. The former Mary Kathleen Uranium mine in Queensland ceased operations in 1982 and was labelled rehabilitated, but later visits to the site found significant seepage from the tailings dam affecting nearby ecosystems. The cost and liability of that pollution legacy lies with the Queensland State Government.

The Environmental Requirements applicable to the Ranger Uranium Mine state that tailings and contaminants must not result in detrimental environmental impacts for at least 10,000 years.5 Water treatment and disposal of tailings add a complicated layer to the timing and cost of any project, exacerbated by the uncertainty of natural elements and the likelihood of heavy rainfall.

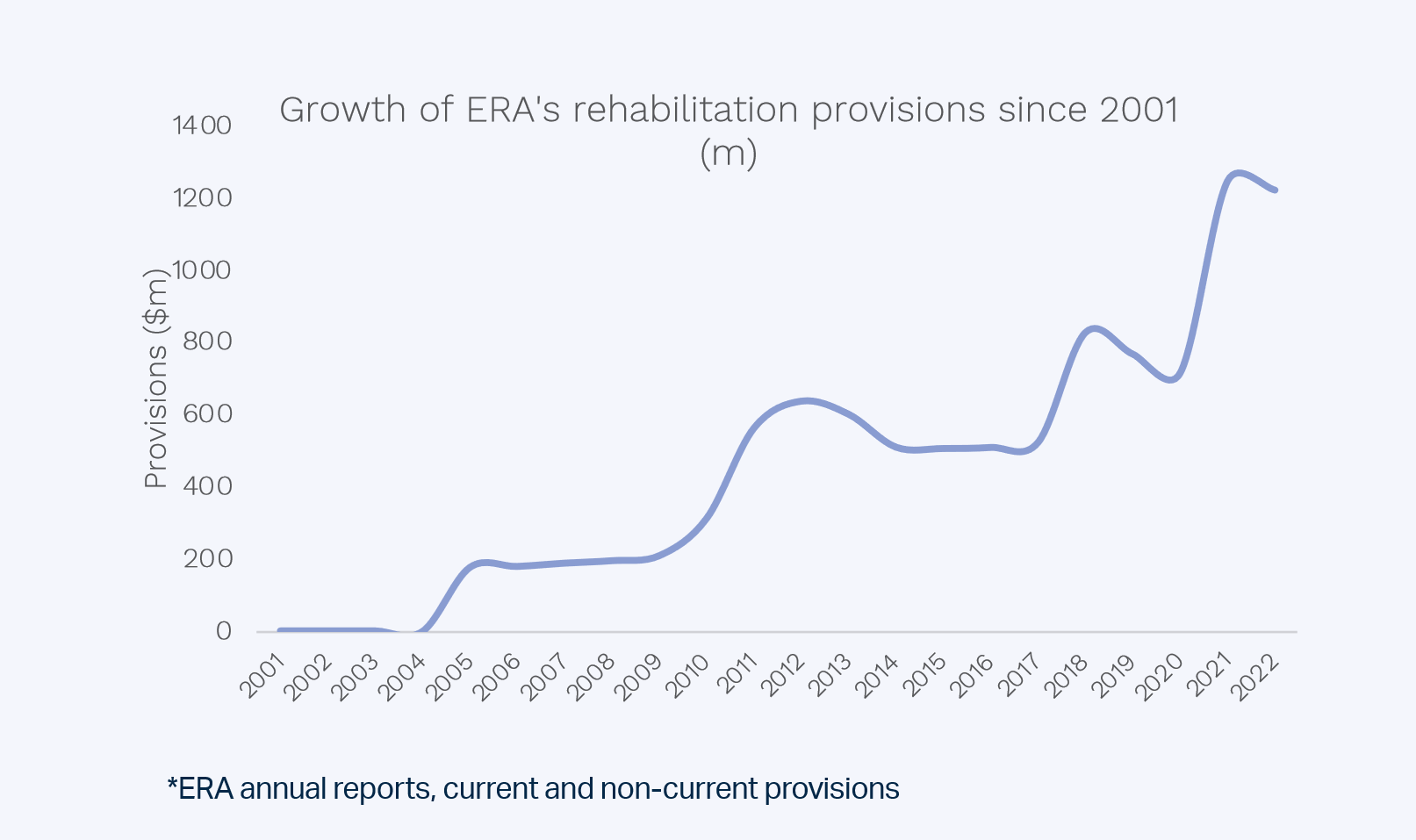

Energy Resources of Australia (ERA), the owner of Ranger Mine (majority owned and controlled by Rio Tinto) hope to obtain a lease extension to yet unmined uranium ore (the Jabiluka deposit). The lure of untapped uranium ore makes remediation of the closed mine particularly important for ERA, who are keen to restore good relationship with traditional owners and eventually be allowed to mine the remaining ore. A news article appeared in September 2023 indicating that traditional owners remain opposed to the mining of Jabiluka and the lease extension that ERA hopes to obtain.6

ERA’s doubling of remediation costs – while staggering – is unlikely to represent the full extent of the costs: the lease agreement on the Ranger Mine includes a requirement that ERA produces yearly cost estimates and presents them for approval to the Commonwealth Government and as remediation continues and issues become better understood costs are likely to continue to rise.

In October this year, the ERA received outcomes for the 2022 Feasibility Study and is in the process of review. Total costs are expected to “materially exceed” previous estimates.

The Alcoa Case

Alcoa’s Environmental Remediation and Asset Retirement Obligation liabilities have grown at 10-11% p.a. over the last five years, with recent increases to provisions driven by the cost inflation the industry has been experiencing. In addition to sector-wide cost increases, Alcoa’s liabilities are likely following an upwards trend due to the design of its Western Australian mining leases: every year, Alcoa is required to obtain approval for its rolling five-year remediation plans. Alcoa’s mining approval process is changing despite no change in regulation – the yearly approval of Alcoa’s 5-year plan by the Western Australian Government has gone from what appeared to be a hurdle-free bureaucratic process to one marred by delays and opposition.

In an attempt to quell criticism from some external stakeholders that the current regulatory system is not fit for purpose, Alcoa has voluntarily applied to the Environmental Protection Agency (EPA) for a mine expansion proposal to demonstrate that their plans are deemed appropriate by a more stringent authority. This happened without any change in legislation, with the company proactively trying to address community concerns.

The Western Australia Forest Alliance (WAFA) has referred Alcoa’s latest 5-year mining plan to the EPA. It is yet unclear whether the EPA will comment on Alcoa’s plans. Either way, the EPA is getting involved in what was once a frictionless approval process.

In sharp contrast to the Ranger Uranium mine example, the relationship between Alcoa and First Nation Groups is not highlighted in the rehabilitation program. There is some risk that this changes in the future.

Conclusion

We believe the costs of mine rehabilitation are a material risk for the sector. Increasingly stringent regulatory requirements and escalating labour costs are causing provisions to compound at 2-3 times the rate of inflation. Chronic and sometimes severe underestimations of rehabilitation provisions can result in substantial off-balance sheet liabilities and earnings risks.

Investors should look for the following risk mitigating factors when investing in miners:

- Best practice remediation design and track record;

- Conservative contingencies particularly in populated areas or areas of cultural or environmental significance, as well as when mining requires the use of large quantities of water and/or takes place in high rainfall areas;

- Constructive and open relationships with all external stakeholders, particularly regulators, neighbouring landowners, environmental groups, and traditional owners of the land; and

- An awareness of local and international standards and expectations for what constitutes acceptable remediation practices.

References

Bourke, J. (2022, July 18). Australia’s abandoned mines rehabilitated. Australian Geographic. https://www.australiangeographic.com.au/topics/history-culture/2022/07/australiasabandoned-mines-rehabilitated/

Dept. of Industry, Tourism and Resources, Mine rehabilitation: Leading practice sustainable development program for the mining industry (2009). Canberra, A.C.T.

Energy Resources of Australia. (2022, October). (rep.). 2022 Ranger Mine Closure Plan.

Kerr, P. (2023, September 3). Traditional owners slam jabiluka extension plan. Australian Financial Review. Retrieved September 7, 2023, from https://www.afr.com/companies/mining/traditionalowners-slam-jabiluka-extension-plan-20230901-p5e1f6#:~:text=Indigenous%20leaders%20have%20slammed%20a,the%20ban%20on%20nuclear%20power

Lock the Gate. (2016, July). (rep.). Mine Rehabilitation and Closure Cost: A Hidden Business Risk.

Mining Act 1992 (Nsw)

Young, R. E., Gann, G. D., Walder, B., Liu, J., Cui, W., Newton, V., Nelson, C. R., Tashe, N., Jasper, D., Silveira, F. A. O., Carrick, P. J., Hägglund, T., Carlsén, S., & Dixon, K. (2022). International principles and standards for the ecological restoration and recovery of mine sites. Restoration Ecology, 30(S2). https://doi.org/10.1111/rec.13771

1 Mining Act 1992 (Nsw)

2 (Bourke, 2022)

3 (Young et al., 2022)

4 Lock the Gate. (2016). (rep.). Mine Rehabilitation and Closure Cost: A Hidden Business Risk.

5 2022 Ranger Mine Closure Plan

6 (Kerr, P. 2023)